Water Softener Plant

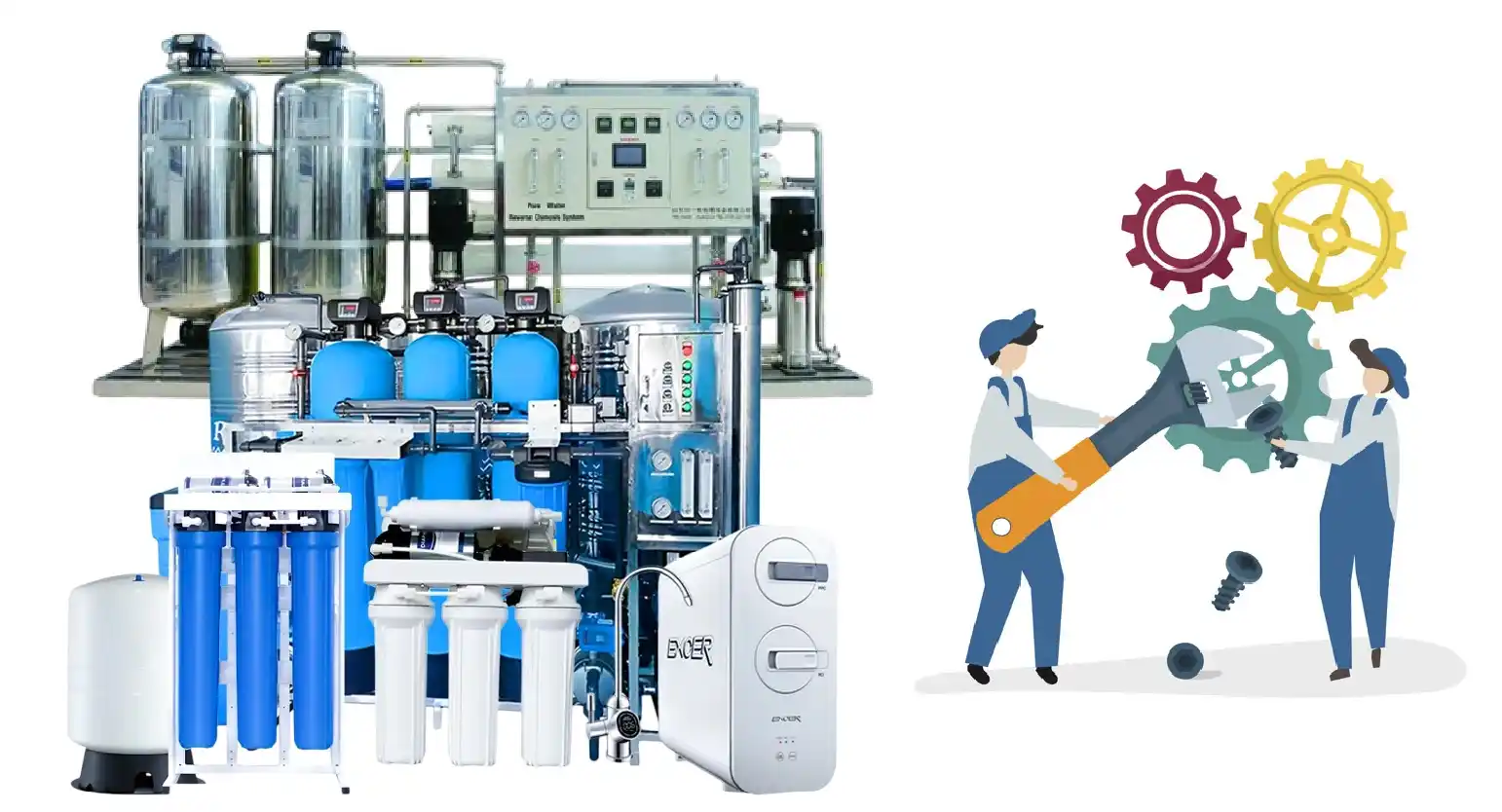

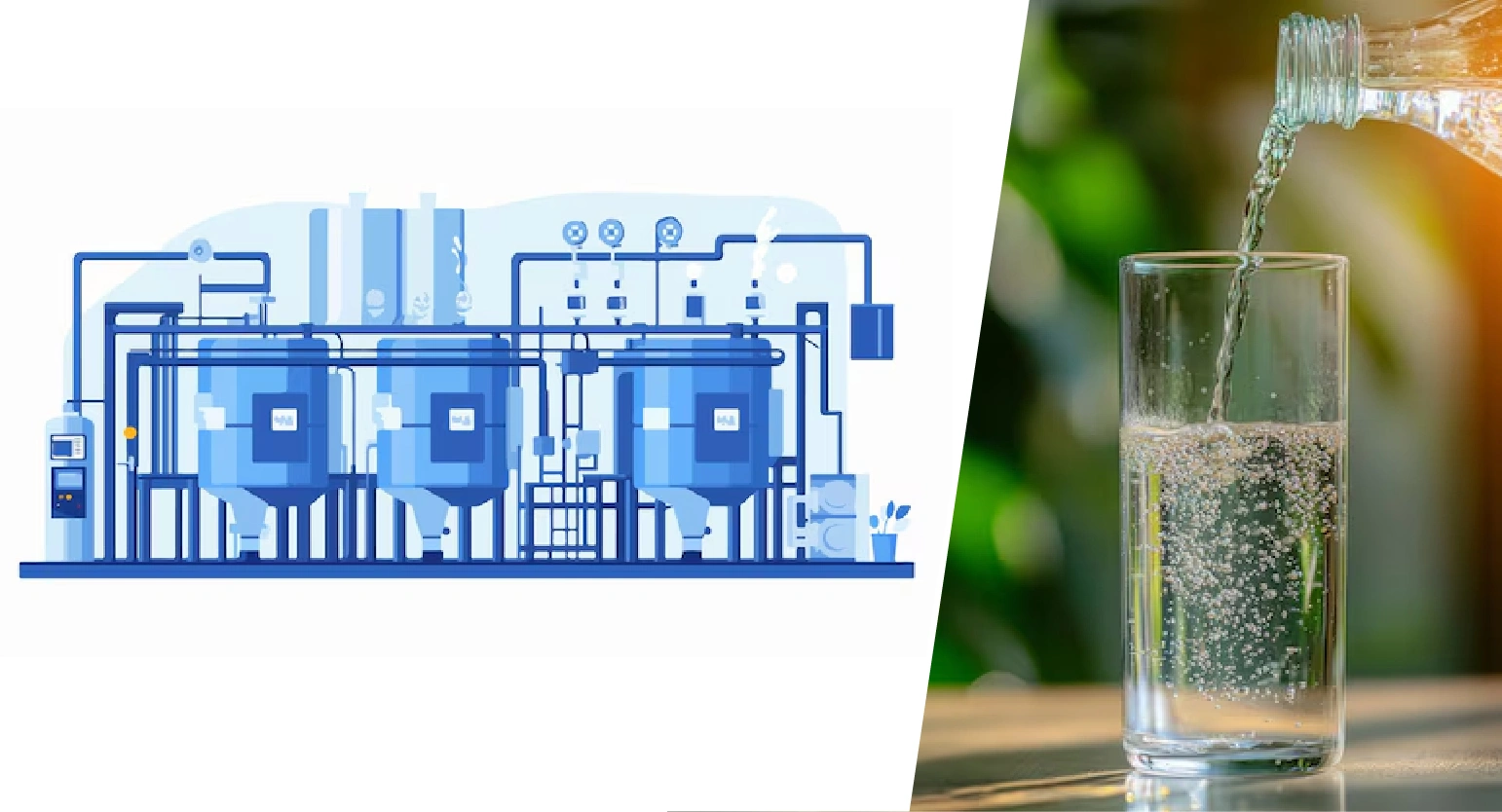

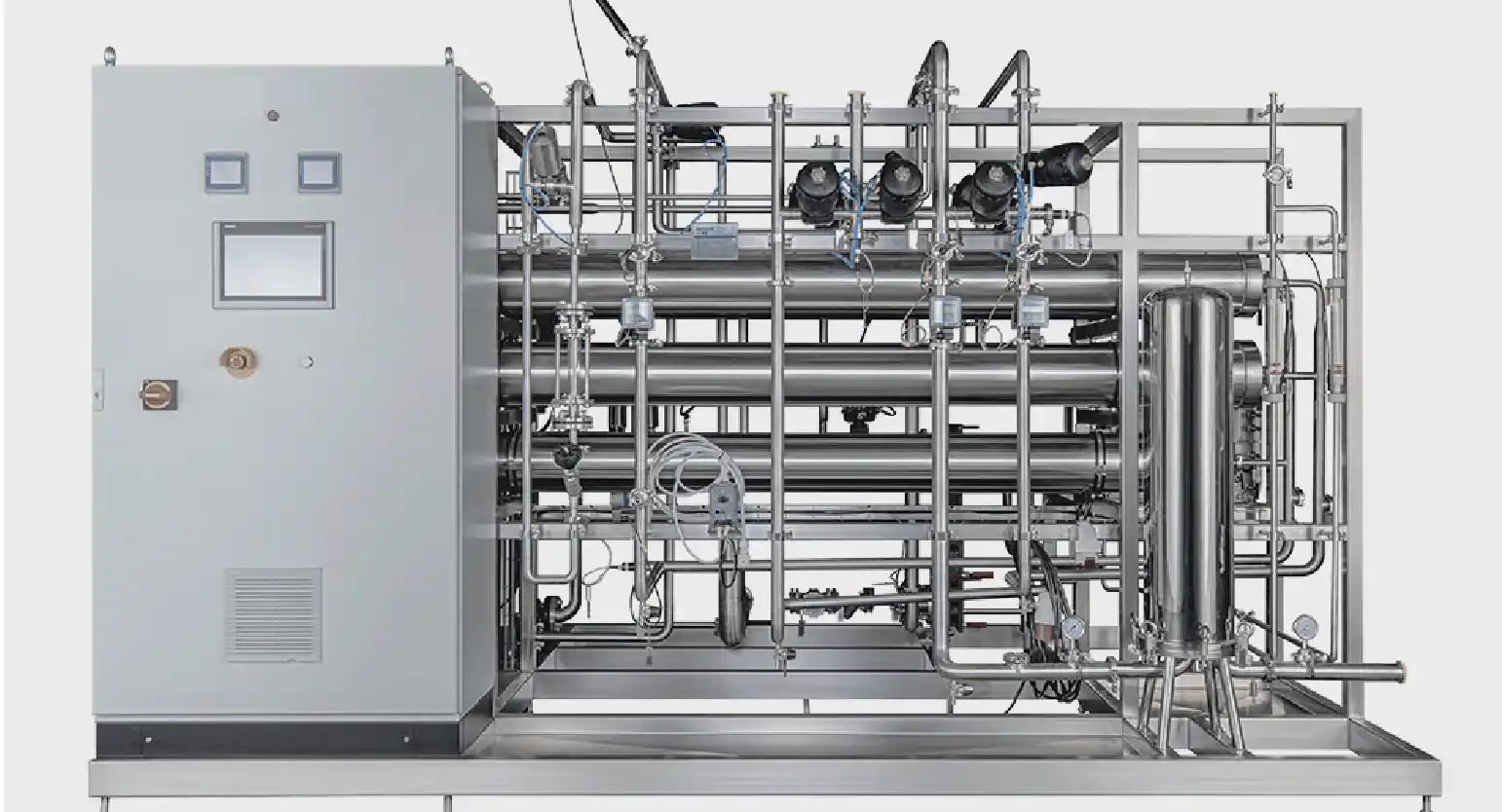

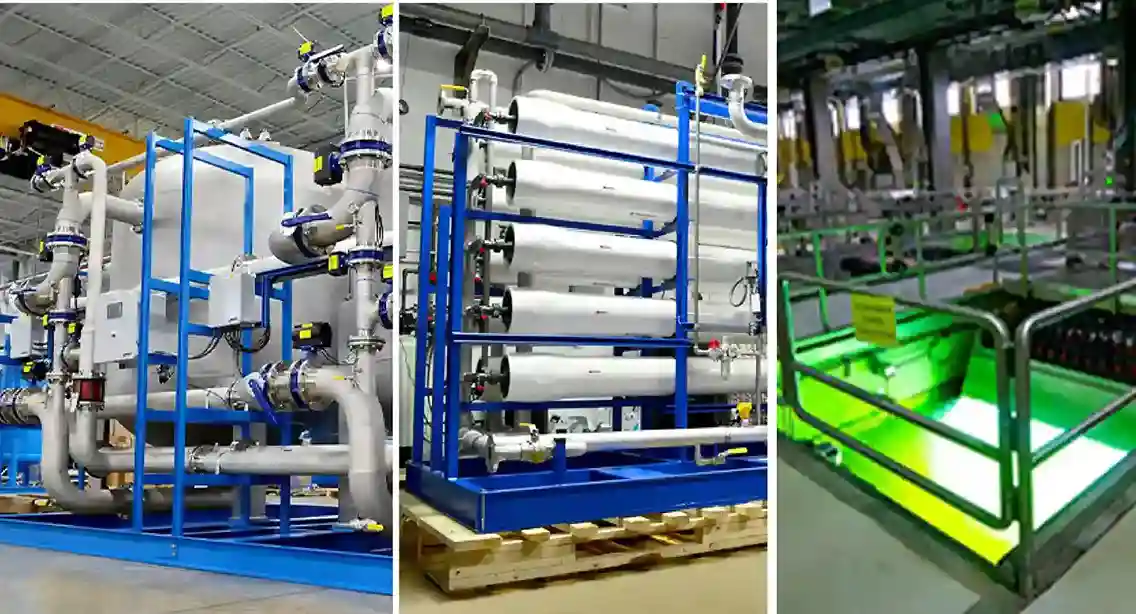

Reverse Osmosis Plant

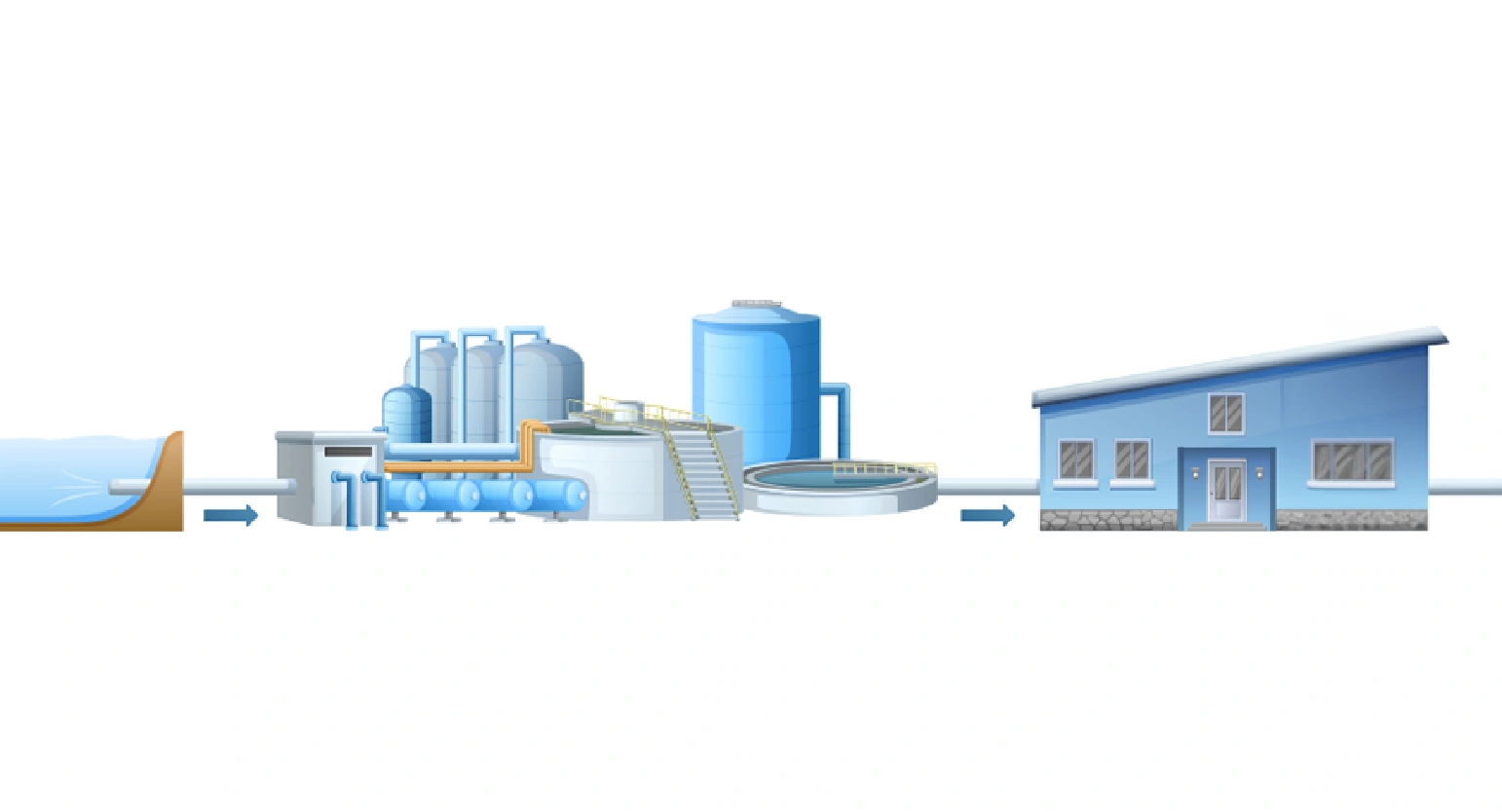

Drinking Water Treatment Plant

Zero Liquid Discharge Plant

Iron Removal Plant

DM Water Plant

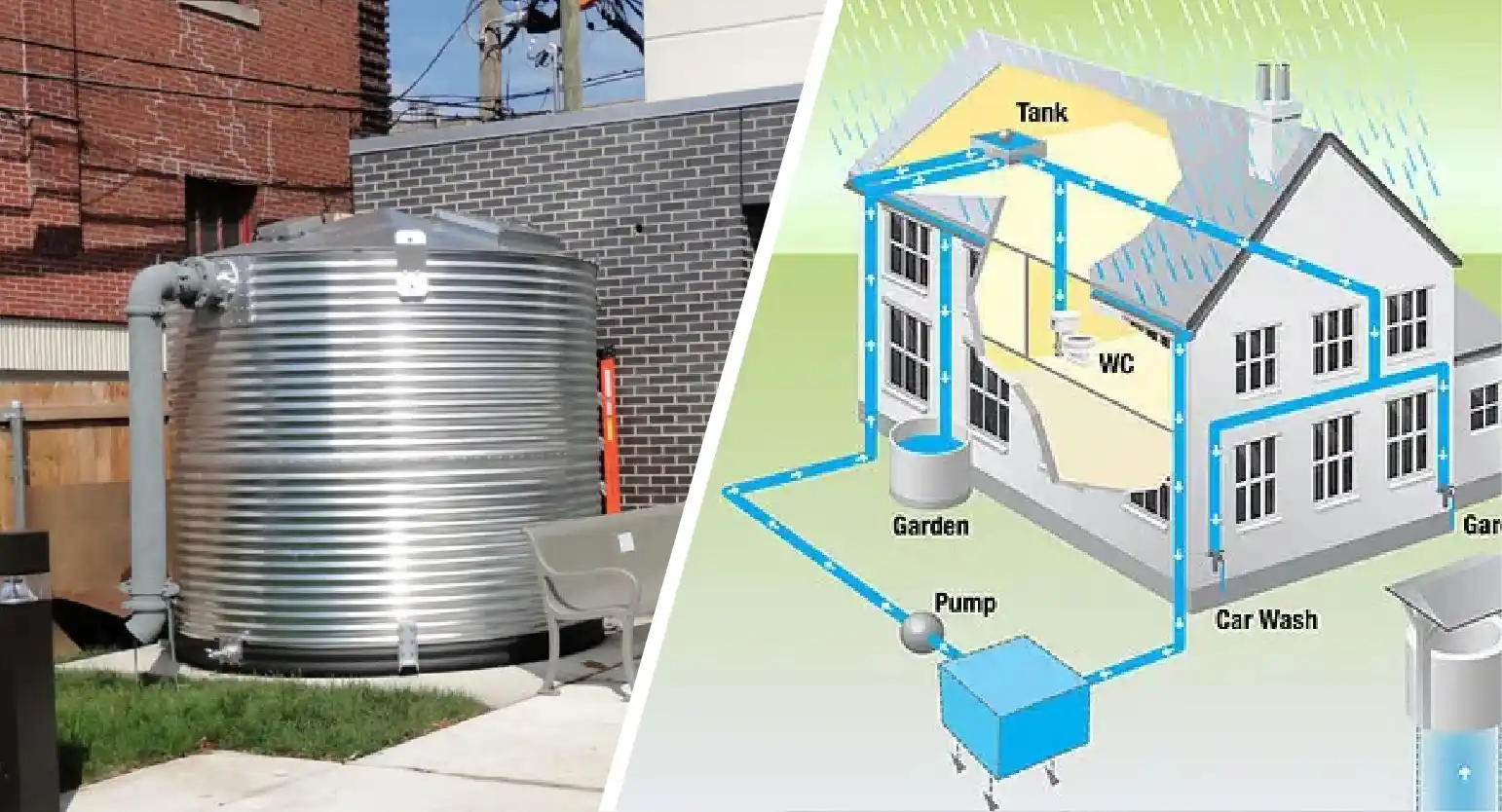

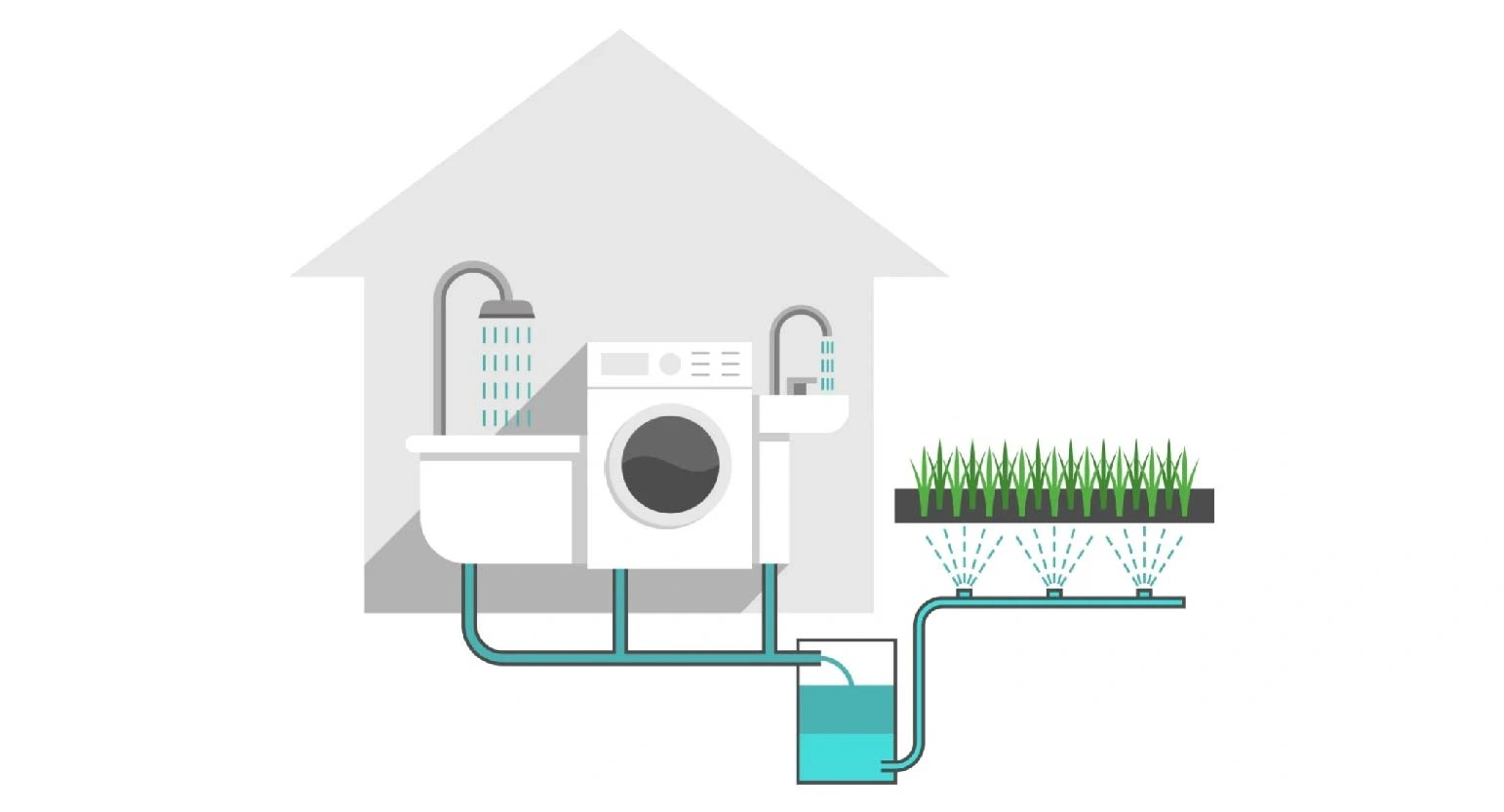

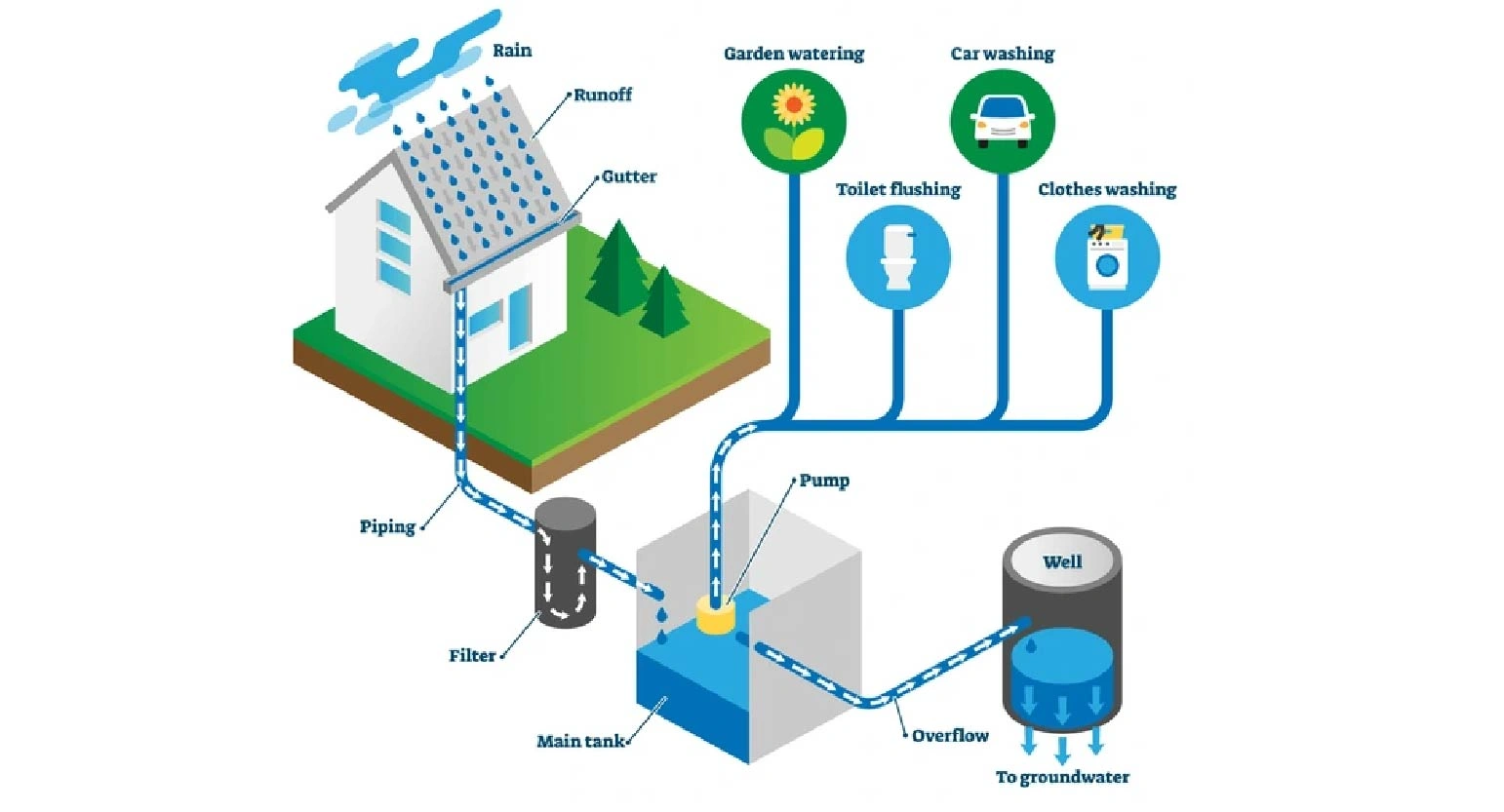

Rain Water Harvesting Plant

Domestic Purifier

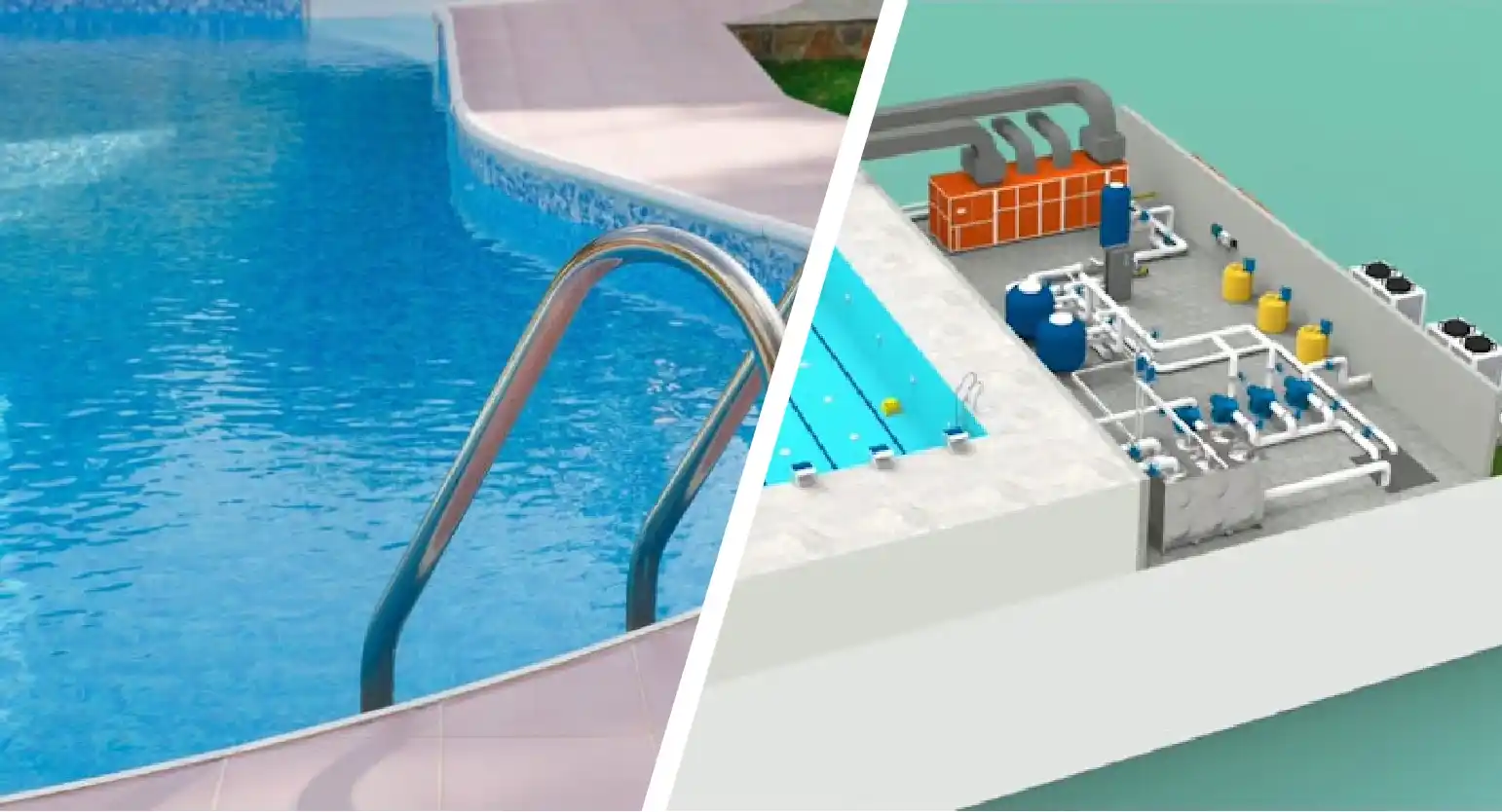

Swimming Pool Plant with Chemical

Pharmaceutical Treatment Plant

Desalination Plant

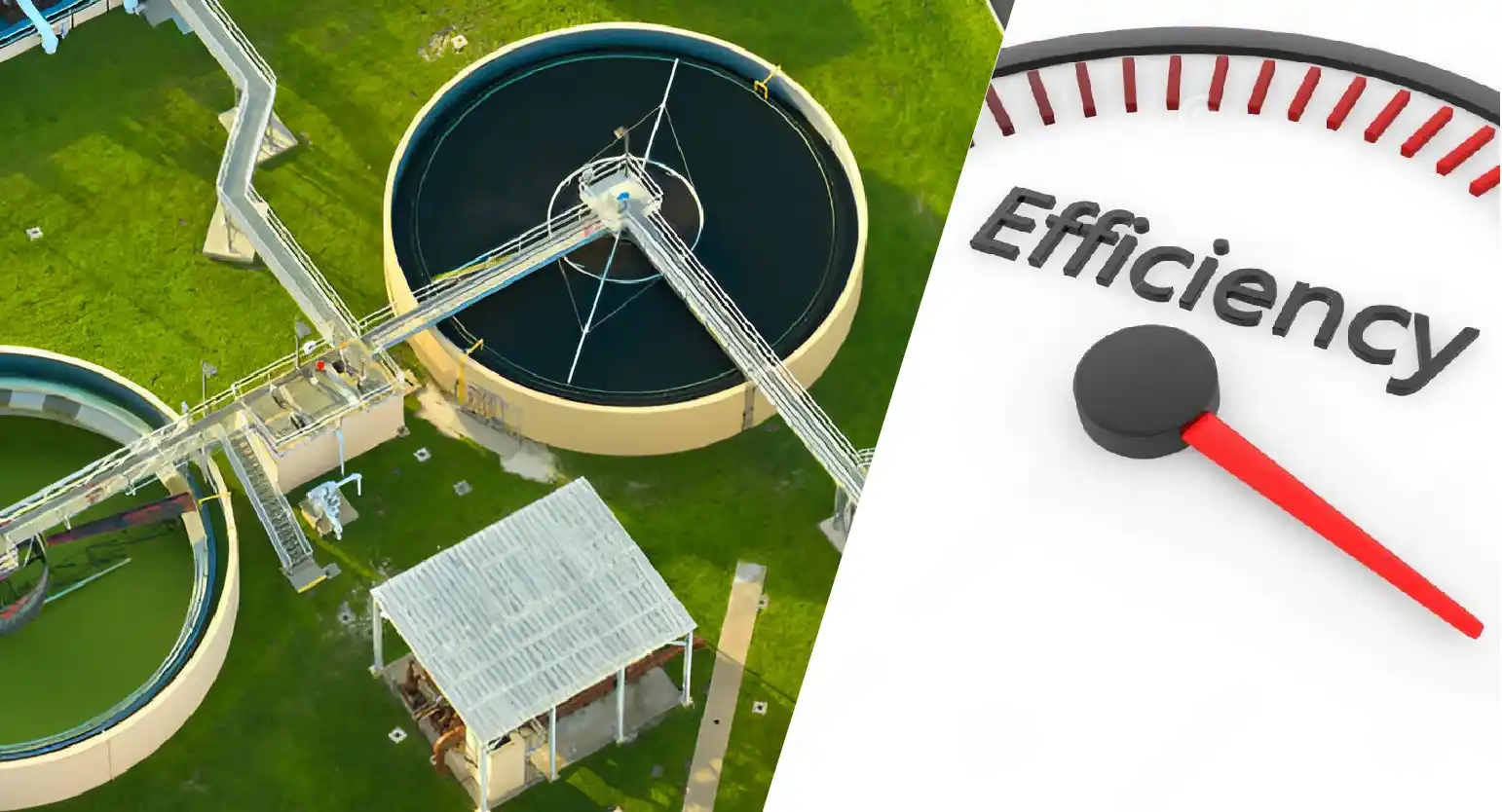

Effluent Treatment Plant (ETP)

Sewage Treatment Plant (STP)

Chlorine Reducer / Dechlorinator

Flocculent

Membrane Biocide

Membrane Cleaner

RO Antiscalant

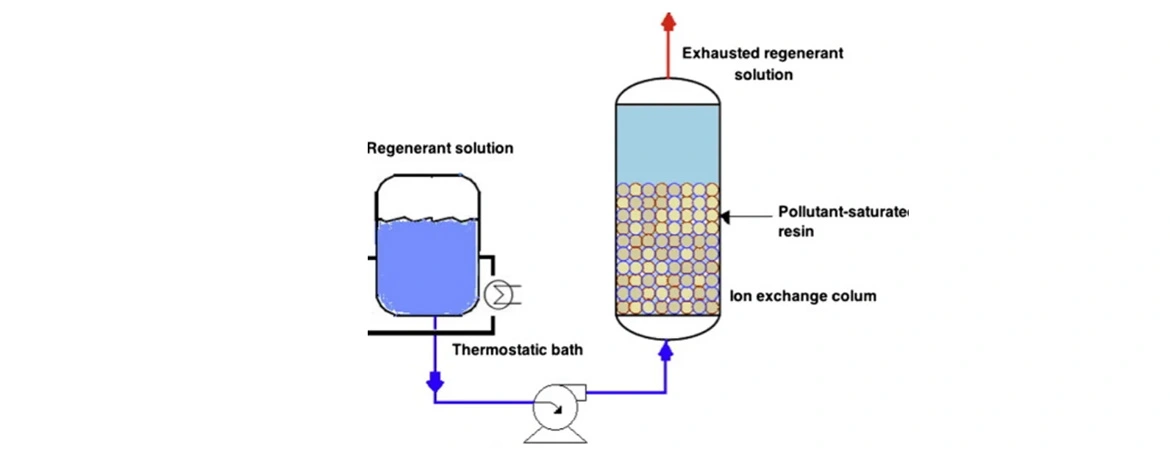

Ion Exchange Resin

Anthracite Filter Media

Activated Carbon

Iron Removal Media

Swimming Pool Chemical

Compact/Box type RO water purifier

Hot Cold Warm RO Purifier

Compact RO purifier

Economy RO Purifier

Filtran

Aqualin

Dow

Vontron

Tecoman

Karofi

Heron

kangaroo

Aquapro

Sanaky

Puricom

Pure Magic

Pristine

Aquafit

Logic Taiwan

Filtran

Micron Filter

Pentec

Eureka

Alkaline

Ecosoft

Pure Pro

Puran

Wilo

Raitapure

y series

deep well pump

BCST

Smart Measurement CO,. Ltd (SMC).

EMTEC

Trundean

Johnson

Filter Pipe

Aqua Taiwan

Green Aqua

Top Klean

Genesys RO

Purifina

In-Line

Easy Pure

UDF

Kemflo

Protech

Deluxe

korihome

Lan Shan

X-Treme

Maas Pure

Smart H2O

Tanklife

Hanna

Pentair

Kamranga

FRP

CNP Pump

Wellsys

KSU

Cascade

Deng Yuan

Livotech

Aquafit

Crystal Water

RFL

Flimtech

Toray

LEO Pump

Gazi Pump

Modina Pump

Extrepure Resin

Puretouch

Harmony

Puro Plus

Puroviet

ADELINO Pump